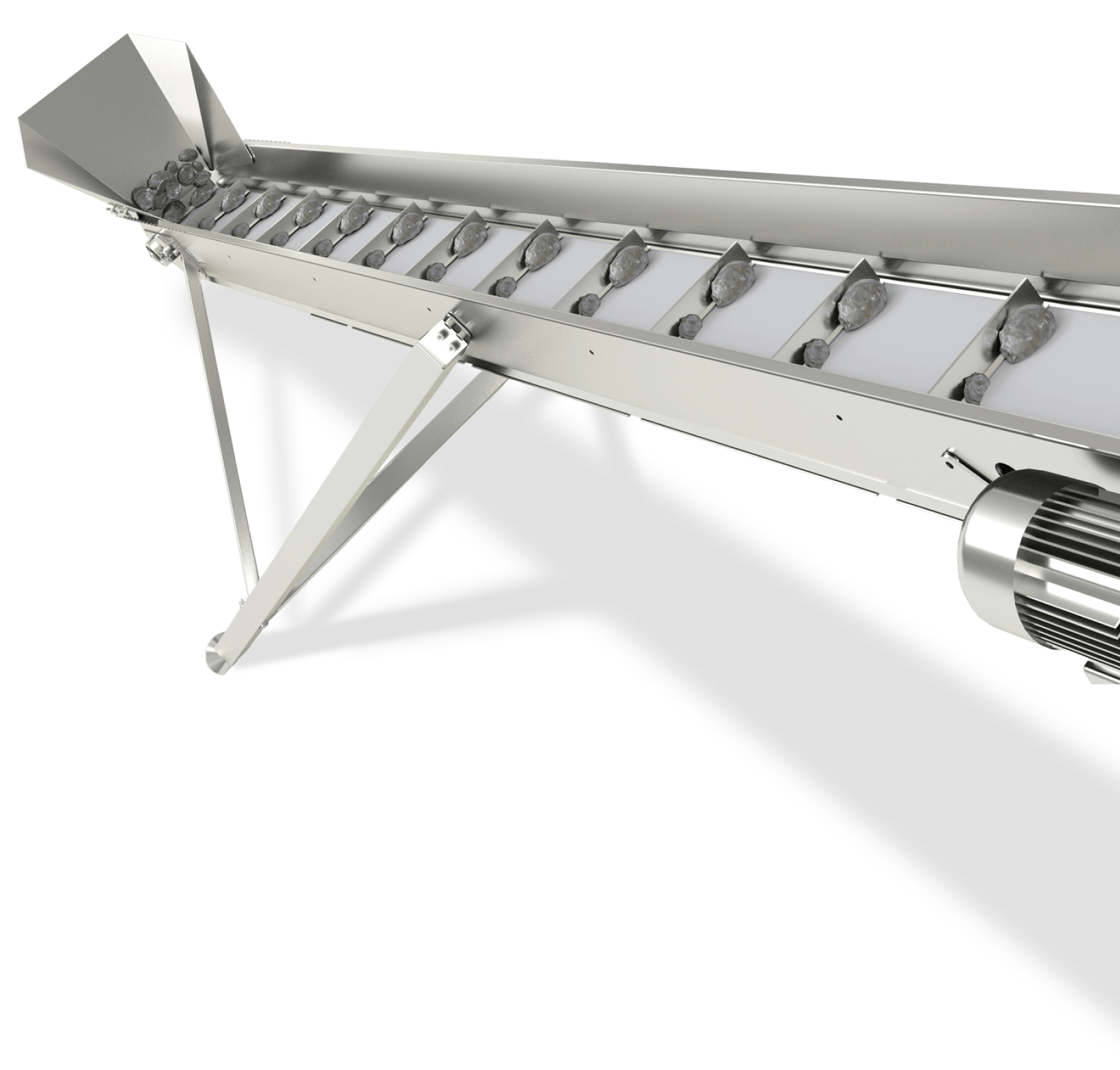

Mini Hopper Oysters fall from the end of the inspection conveyor into the mini hopper, where the elevator picks them up and carries them into the singulator.

Evenly spaced cleats transport oysters from the mini hopper into the singulator.

The singulator gently tumbles oysters and distributes them single file into the grader.

This is a sensor that will automatically pause the machine if there happens to be a buildup of oysters.

A custom designed 4-axis sensor array images the oysters and communicates size data to the control screen and motor column.

The control screen is an industrial touch screen panel PC - All program settings and operation of the grader is carried out using the control screen.

Oysters are directed into one of 8 output chutes by an internal J-curve, capable of repositioning more than 10 times every second

Oysters are directed into one of 8 output chutes by an internal J-curve, capable of repositioning more than 10 times every second

The control screen is an industrial touch screen panel PC - All program settings and operation of the grader is carried out using the control screen.

Our proven distribution system has one moving part and can direct graded oysters to any of 8 programmable output chutes. Grade and count oysters directly into many types of oyster basket systems as well as into sales bags or buckets.

The sorting conveyor takes oysters from the creep conveyor to the elevator, it is used to manually inspect product and remove foreign objects. Speed and start/stop functions are controllable on the power box, which is mounted to the sorting conveyor frame.

Power box is mounted to the sorting conveyor frame. Comes standard with height-adjustable foot inserts. Optional castor wheels are available.